Let’s work together

The possibilities are endless

Secondary packaging is the grouping of several individual items into a secondary container. Depending on your product this may also mean a single product into the container. Secondary packaging solutions are provided after your product has been packaged and is ready to be placed in the shipping container. With so many secondary automated packaging equipment options on the market, how do you know which one to choose?

Your solution will be based strictly on your needs. At BPA, factors such as product and package type, speed, number of recipes and pack patterns and more will be taken into consideration when determining a secondary packaging solution best for you. BPA has a diverse team of experts on hand to assist you through this process.

Products

- Gravity 100 Case Packer

- Gravity 100R Case Packer

- CubeMaster 200 Case Packer

- CubeMaster 200i Case Packer

- CubeMaster 300 Case Packer

- CubeMaster 300i Case Packer

- Gantry 100 Case Packer

- Gantry 200 Case Packer

- Gantry 200i Case Packer

- Gantry 300 Swing Case Packer

- Spider 100 Case Packer

- Spider 100i Case Packer

- Spider 200 Case Packer

- Spider 200i Case Packer

- Spider 300 Case Packer

- Spider V series

- Spider Q series

- Spider 300v Case Packer

- SnackMaster 200 Case Packer

- SnackMaster 200i Case Packer

- Wraparound 100

- Wraparound 200

- Wraparound 300

- Cartoner 100

- Cartoner 100c

- Variety Pack in Sack or Case

- Shaker-Compactor-Sealer (SCS)

- Collator 200 Semi Automatic Packing

- Bag in Bag Solutions - Jongerius Hanco

- Strip Sachet Machine - Jongerius Hanco

For these industries:

Cartoner 100

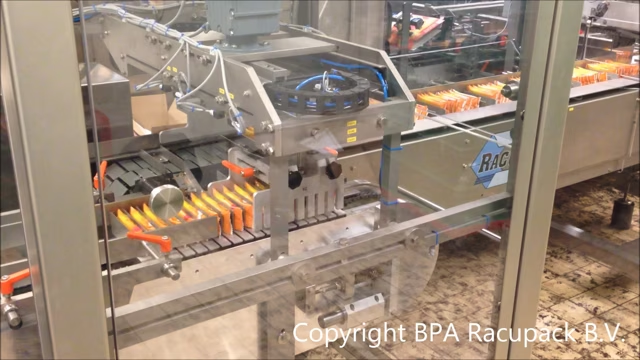

Cartoner 100 Horizontal Load Carton Erector, Carton Loader & Carton Seal

Process up to 100 pre-glued cartons per minute with the Cartoner 100 Intermittent Motion cartoning machine. Because of its intermittent operation, the production speed of this machine is high in comparison to its relatively small footprint. This almost fully stainless steel machine offers a high standard of cleanliness. The hygienic building principle makes this machine highly suitable for the food production industry. Main drive functions are servo driven or AC drives, resulting in highly controlled and accurate movements. Engage with us to discuss your specific products and cartons. We will gladly inform you about the maximum processing capacity of this excellent intermittent motion cartoning machine.

As every production environment is unique, every organization requires a tailored solution. Challenge us and put our experts to the test, to devise the solution that fits your process like a glove.