Travaillons ensemble

Les possibilités sont infinies

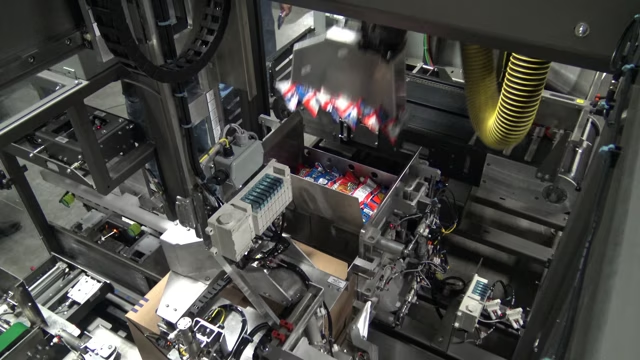

L'emballage secondaire est le regroupement de plusieurs articles individuels dans un conteneur secondaire. En fonction de votre produit, il peut également s'agir d'un seul produit dans le conteneur. Les solutions d'emballage secondaire sont fournies une fois que votre produit a été emballé et qu'il est prêt à être placé dans le conteneur d'expédition. Avec autant d'options d'équipement d'emballage secondaire automatisé sur le marché, comment savoir lequel choisir ?

Votre solution sera basée strictement sur vos besoins. Chez BPA, des facteurs tels que le type de produit et d'emballage, la vitesse, le nombre de recettes et de modèles d'emballage, etc. sont pris en considération pour déterminer la solution d'emballage secondaire qui vous convient le mieux. BPA dispose d'une équipe diversifiée d'experts pour vous aider tout au long de ce processus.

Produits

- Emballeuse Gravity 100

- Emballeuse Gravity 100R

- CubeMaster 200 Emballeuse

- CubeMaster 200i Emballeuse

- CubeMaster 300 Emballeuse

- CubeMaster 300i Emballeuse

- Gantry 100 Emballeuse

- Gantry 200 Emballeuse

- Gantry 200i Emballeuse

- Gantry 300 Swing Emballeuse

- Spider 100 Emballeuse

- Spider 100i Emballeuse

- Spider 200 Emballeuse

- Spider 200i Emballeuse

- Spider 300 Emballeuse

- Série Spider V

- Série Spider Q

- Spider 300v Emballeuse

- SnackMaster 200 Emballeuse

- SnackMaster 200i Emballeuse

- Wraparound 100

- Wraparound 200

- Wraparound 300

- Cartoner 100

- Cartoner 100c

- Pack varié en sac ou en caisse

- Shaker-Compactor-Sealer (SCS)

- Collator 200 Emballage semi-automatique

- Solutions Sac dans Sac - Jongerius Hanco

- Machine à sachets en bande - Jongerius Hanco

Pour ces industries :

Encaisseuse Gantry 200i

Encaissage vertical à grande vitesse avec élévateur de caisses intégré

Chaque environnement de production étant unique, chaque organisation a besoin d'une solution sur mesure. Mettez-nous au défi et mettez nos experts à l'épreuve, afin de concevoir la solution qui s'adapte parfaitement à votre processus. N'hésitez pas à nous contacter dès aujourd'hui !